Abaqus分析球的下落弹起问题案例

ABAQUS计算指导10:球的下落弹起问题

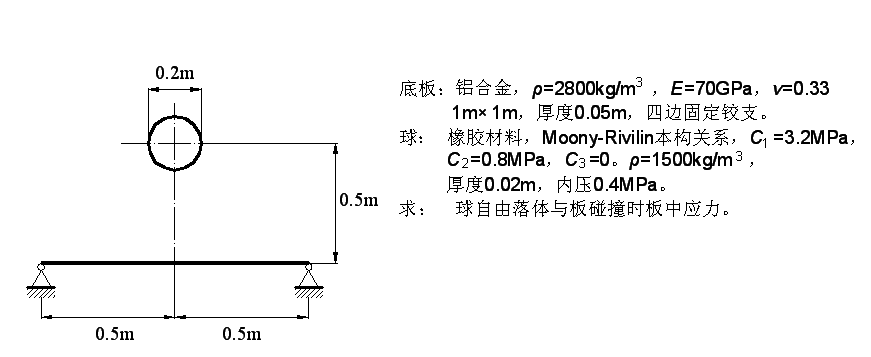

用轴对称壳单元模拟打足气的球衣自由落体方式落在铝板上。铝合金板厚度0.05mm,大小1×1m,四边简支。材质E=70GPa,μ=0.33,因为是动力学问题,ρ=2800kg/m3是*备的参数。球皮的厚度为0.02m,其材料通常为类似于橡胶的gao分子材料,用超弹性本构关系可以很好模拟。本题用Mooney-Rivlin的应变能密度函数,C1=3.2MPa,C2=0.8MPa,D=0。材料密度ρ=1500kg/m3,球的内压与大气压力的压差p=0.4MPa(气不是很足,但气足的不好算),整个过程中都要考虑重力。计算落地反弹过程。

球是密闭容器。受到外载荷的作用后,内压随变形变化,采用常内压p无法模拟这一变化。

文件与路径

该题按常内压求解的算例,ExpAbq101,命令流为ExpAbq101.inp。本题作为密闭容器的变内压解法见命令流ExpAbq102.inp,因为变形很大,两种情况的求解结果也是大不一样。

一 部件

创建部件,用三维可变形壳造底板和球,命名。

球:3D,Deformable,Shell,Revolution,1。轴右半圆,旋转360°。

板:3D,Deformable,Shell,Planer,1。-0.5,-0.5; 0.5,-0.5; 0.5, 0.5; -0.5, 0.5。

二 性质

1 创建材料:

将材料命名,球的材料:Density:ρ=1500kg/m3;Hyperelastic,Strain Energy potential:Mooney-Rivlin;Input Source:Coefficients;C1=3.2MPa,C2=0.8MPa,D=0。

将材料命名,底板材料:Density:ρ=2800kg/m3;Elasticity,Elastic:E=70GPa,ν=0.33。

2 创建截面:

分别命名,壳,各向同性,厚度,选材料名,关闭。

3 将截面的性质附加到部件上:

选中Prat-*,将Section-*信息注入Part-*。

三 组装

创建计算实体,以Prat-*为原形,用Dependent方式生成实体。

用旋转、平移等方法把底板放置到球的正下方。

四 分析步

创建非线性动力学分析步,命名为Step-1, Dynamic, Explicit,几何非线性打开,Δt=0.315,0~0.315s(time period 0.315),注释:落体阶段。

创建非线性动力学分析步,命名为Step-2,Dynamic,Explicit,非线性开,Δt=0.015,0.315~0.33s(time period 0.015),注释:碰撞阶段。

五 接触

1 创建相互作用属性:

命名,属性为接触,性质:无(无摩擦有限滑动)。

2 创建接触对:

创建轮轴接触对,在初始步Step-1中,命名,面-面接触,主动面选球外表面,被动面选底板上表面。

六 载荷

1 施加位移边界条件:

命名,只约束底板四边自由度ux、uy、uz。

2 创建载荷:

重力

时间历程:平滑历程,0s:0幅度;0.1s:1幅度;1.0s:1幅度;命名幅度-时间历程文件为Amp -1。顶部下拉菜单,Tools,Amplitude,Create,Amp-1,Smooth step,0,0,0.1,0,1,1。

重力载荷,y方向,-9.8,Amp-1。

内压

幅度-时间历程文件可以不要。若想做,

时间历程:突变历程,0s:1幅度;1.0s:1幅度;命名幅度-时间历程文件为Amp -2。顶部下拉菜单,Tools,Amplitude,Create,Amp-2,Smooth step,0,1,1,1。

球的内压载荷,压强,作用于球的内壁,0.4MPa,Amp-2。

七 网格

对部件Prat-1、Prat-2分别进行。

1 网格控制:板,可以将中央接触区单分区。球壁,较好Sweep。

2 种子:针对部件,全局种子大约间距自己设计。非线性动力学分析,网格分粗一些,否则计算缓慢。

2 划网格。

八 建立项目

命名为***,选择完整分析,其余不变,OK。

九 观察结果

碰撞瞬间:

命令流

*Heading

** Job name: ExpAbq101 Model name: Model-1

*Preprint, echo=NO, model=NO, history=NO, contact=NO

**

** PARTS

*Part, name=Part-1

*End Part

*Part, name=Part-2

*End Part

**

** ASSEMBLY

*Assembly, name=Assembly

*Instance, name=Part-1-1, part=Part-1

*Node

1, 0.0, 0.40, 0.0

11, 0.0, 0.60, 0.0

*Ngen,Line=C ,Nset=Part1

1, 11, 1, ,0.00,0.50,0.00,0.00,0.00,1.00

*Nset, nset=Part1C, internal, generate

2, 10, 1

*Ncopy, Change Number=10, Old Set=Part1C, Shift, Multiple=20

0.0, 0.0, 0.0

0.0, 0.0, 0.0, 0.0,1.0,0.0,18.0

*Element, type=S3

1, 1, 12, 2

11, 1, 22, 12

21, 1, 32, 22

31, 1, 42, 32

41, 1, 52, 42

51, 1, 62, 52

61, 1, 72, 62

71, 1, 82, 72

81, 1, 92, 82

91, 1,102, 92

101, 1,112,102

111, 1,122,112

121, 1,132,122

131, 1,142,132

141, 1,152,142

151, 1,162,152

161, 1,172,162

171, 1,182,172

181, 1,192,182

191, 1, 2,192

10, 10, 20, 11

20, 20, 30, 11

30, 30, 40, 11

40, 40, 50, 11

50, 50, 60, 11

60, 60, 70, 11

70, 70, 80, 11

80, 80, 90, 11

90, 90,100, 11

100,100,110, 11

110,110,120, 11

120,120,130, 11

130,130,140, 11

140,140,150, 11

150,150,160, 11

160,160,170, 11

170,170,180, 11

180,180,190, 11

190,190,200, 11

200,200, 10, 11

*Element, type=S4R

2, 12, 13, 3, 2

192, 2, 3,193,192

*ELGEN, Elset=Part1

2, 8, 1, 1, 19, 10, 10

*ELGEN, Elset=Part1

192, 8, 1, 1

*Node

400,0.0,0.5,0.0

*Elset, elset=Part1, internal, instance=Part-1-1, generate

1,200, 1

** Section: Section-1

*Shell Section, elset=Part1, material=Material-1

0.02, 5

*End Instance

**

*Instance, name=Part-2-1, part=Part-2

*Node

1,-0.20, 0.00, 0.20

10, 0.20, 0.00, 0.20

91,-0.20, 0.00,-0.20

100, 0.20, 0.00,-0.20

*Ngen, ,Nset=Part2A

1, 91,10, , , , , , ,

*Ngen, ,Nset=Part2B

10,100,10, , , , , , ,

*Nfill, Nset=Part2

Part2A, Part2B, 9, 1

*Element, type=S4R

1, 1, 2, 12, 11

*Elgen, Elset=Part2

1, 9, 1, 1, 9, 10, 9

*Elset, elset=Part2, internal, instance=Part-2-1, generate

1, 81, 1

** Section: Section-2

*Shell Section, elset=Part2, material=Material-2

0.05, 5

*End Instance

**

*Elset, elset=Part1in, internal, instance=Part-1-1, generate

1,200, 1

*Surface, type=ELEMENT, name=Part1inS, internal

Part1in, Sneg

*Elset, elset=Part1out, internal, instance=Part-1-1, generate

1,191, 10

2,192, 10

3,193, 10

*Surface, type=ELEMENT, name=Part1outS, internal

Part1out, Spos

*Elset, elset=Part2out, internal, instance=Part-2-1, generate

1, 81, 1

*Surface, type=ELEMENT, name=Part2outS, internal

Part2out, SPOS

*Nset, nset=AC, internal, instance=Part-2-1, generate

1, 10, 1

1, 91, 10

10,100, 10

91,100, 1

*End Assembly

*Amplitude, name=Amp-1, definition=SMOOTH STEP

0.0, 0.0, 0.1, 1.0, 1.0, 1.0

**

** MATERIALS

*Material, name=Material-1

*Density

1500.,

*Hyperelastic, mooney-rivlin

3.2e+06,800000., 0.

*Material, name=Material-2

*Density

2800.,

*Elastic

7e+10, 0.33

** INTERACTION PROPERTIES

*Surface Interaction, name=IntProp-1

** ----------------------------------------------------------------

** STEP: Step-1

*Step, name=Step-1

*Dynamic, Explicit

, 0.32

*Bulk Viscosity

0.06, 1.2

** BOUNDARY CONDITIONS

** Name: BC-1 Type: Displacement/Rotation

*Boundary

AC, 1, 3

** LOADS

** Name: Load-1 Type: Pressure

*Dsload

Part1inS, P, 400000.

** Name: Load-2 Type: Gravity

*Dload, amplitude=Amp-1

, GRAV, 9.8, 0., -1., 0.

** INTERACTIONS

** Interaction: Int-1

*Contact Pair, interaction=IntProp-1, mechanical constraint=KINEMATIC, cpset=Int-1

Part2outS, Part1outS

** OUTPUT REQUESTS

*Restart, write, number interval=1, time marks=NO

** FIELD OUTPUT: F-Output-1

*Output, field, variable=PRESELECT

** HISTORY OUTPUT: H-Output-1

*Output, history, variable=PRESELECT

*End Step

** ----------------------------------------------------------------

** STEP: Step-2

*Step, name=Step-2

*Dynamic, Explicit

, 0.015

*Bulk Viscosity

0.06, 1.2

** OUTPUT REQUESTS

*Restart, write, number interval=1, time marks=NO

** FIELD OUTPUT: F-Output-1

*Output, field, variable=PRESELECT

** HISTORY OUTPUT: H-Output-1

*Output, history, variable=PRESELECT

*End Step

*Heading

** Job name: ExpAbq102 Model name: Model-1

*Preprint, echo=NO, model=NO, history=NO, contact=NO

*PHYSICAL CONSTANTS, ABSOLUTE ZERO=-273.15

**

** PARTS

*Part, name=Part-1

*End Part

*Part, name=Part-2

*End Part

**

** ASSEMBLY

*Assembly, name=Assembly

*Instance, name=Part-1-1, part=Part-1

*Node

1, 0.0, 0.40, 0.0

11, 0.0, 0.60, 0.0

*Ngen,Line=C ,Nset=Part1

1, 11, 1, ,0.00,0.50,0.00,0.00,0.00,1.00

*Nset, nset=Part1C, internal, generate

2, 10, 1

*Ncopy, Change Number=10, Old Set=Part1C, Shift, Multiple=20

0.0, 0.0, 0.0

0.0, 0.0, 0.0, 0.0,1.0,0.0,18.0

*Element, type=S3

1, 1, 12, 2

11, 1, 22, 12

21, 1, 32, 22

31, 1, 42, 32

41, 1, 52, 42

51, 1, 62, 52

61, 1, 72, 62

71, 1, 82, 72

81, 1, 92, 82

91, 1,102, 92

101, 1,112,102

111, 1,122,112

121, 1,132,122

131, 1,142,132

141, 1,152,142

151, 1,162,152

161, 1,172,162

171, 1,182,172

181, 1,192,182

191, 1, 2,192

10, 10, 20, 11

20, 20, 30, 11

30, 30, 40, 11

40, 40, 50, 11

50, 50, 60, 11

60, 60, 70, 11

70, 70, 80, 11

80, 80, 90, 11

90, 90,100, 11

100,100,110, 11

110,110,120, 11

120,120,130, 11

130,130,140, 11

140,140,150, 11

150,150,160, 11

160,160,170, 11

170,170,180, 11

180,180,190, 11

190,190,200, 11

200,200, 10, 11

*Element, type=S4R

2, 12, 13, 3, 2

192, 2, 3,193,192

*ELGEN, Elset=Part1

2, 8, 1, 1, 19, 10, 10

*ELGEN, Elset=Part1

192, 8, 1, 1

*Node

400,0.0,0.5,0.0

*Nset, nset=Part1RP, internal, instance=Part-1-1

400

*Elset, elset=Part1, internal, instance=Part-1-1, generate

1,200, 1

** Section: Section-1

*Shell Section, elset=Part1, material=Material-1

0.02, 5

** FLUID ELEMENTS

*Element, type=F3D3, Elset=FLUIDBot

1001, 1, 2, 12

1011, 1, 12, 22

1021, 1, 22, 32

1031, 1, 32, 42

1041, 1, 42, 52

1051, 1, 52, 62

1061, 1, 62, 72

1071, 1, 72, 82

1081, 1, 82, 92

1091, 1, 92,102

1101, 1,102,112

1111, 1,112,122

1121, 1,122,132

1131, 1,132,142

1141, 1,142,152

1151, 1,152,162

1161, 1,162,172

1171, 1,172,182

1181, 1,182,192

1191, 1,192, 2

*Element, type=F3D4, Elset=FLUIDMid

1002, 2, 3, 13, 12

1192,192,193, 3, 2

*ELGEN, Elset=FLUIDMid

1002, 8, 1, 1, 19, 10, 10

*ELGEN, Elset=FLUIDMid

1192, 8, 1, 1

*Element, type=F3D3, Elset=FLUIDTop

1010, 11, 20, 10

1020, 11, 30, 20

1030, 11, 40, 30

1040, 11, 50, 40

1050, 11, 60, 50

1060, 11, 70, 60

1070, 11, 80, 70

1080, 11, 90, 80

1090, 11,100, 90

1100, 11,110,100

1110, 11,120,110

1120, 11,130,120

1130, 11,140,130

1140, 11,150,140

1150, 11,160,150

1160, 11,170,160

1170, 11,180,170

1180, 11,190,180

1190, 11,200,190

1200, 11, 10,200

*Elset, elset=FLUID1, internal

FLUIDBot, FLUIDMid, FLUIDTop

*FLUID PROPERTY, REF NODE=Part1RP, TYPE=PNEUMATIC,

ELSET=FLUID1, AMBIENT=100000.0

*FLUID DENSITY, PRESSURE=100000.0, TEMPERATURE=27.0

1.024,

*End Instance

**

*Instance, name=Part-2-1, part=Part-2

*Node

1,-0.20, 0.00, 0.20

10, 0.20, 0.00, 0.20

91,-0.20, 0.00,-0.20

100, 0.20, 0.00,-0.20

*Ngen, ,Nset=Part2A

1, 91,10, , , , , , ,

*Ngen, ,Nset=Part2B

10,100,10, , , , , , ,

*Nfill, Nset=Part2

Part2A, Part2B, 9, 1

*Element, type=S4R

1, 1, 2, 12, 11

*Elgen, Elset=Part2

1, 9, 1, 1, 9, 10, 9

*Elset, elset=Part2, internal, instance=Part-2-1, generate

1, 81, 1

** Section: Section-2

*Shell Section, elset=Part2, material=Material-2

0.05, 5

*End Instance

**

*Elset, elset=Part1in, internal, instance=Part-1-1, generate

1,200, 1

*Surface, type=ELEMENT, name=Part1inS, internal

Part1in, Sneg

*Elset, elset=Part1out, internal, instance=Part-1-1, generate

1,191, 10

2,192, 10

3,193, 10

*Surface, type=ELEMENT, name=Part1outS, internal

Part1out, Spos

*Elset, elset=Part2out, internal, instance=Part-2-1, generate

1, 81, 1

*Surface, type=ELEMENT, name=Part2outS, internal

Part2out, SPOS

*Nset, nset=AC, internal, instance=Part-2-1, generate

1, 10, 1

1, 91, 10

10,100, 10

91,100, 1

*Nset, nset=Part1RP, internal, instance=Part-1-1

400

*End Assembly

*Amplitude, name=Amp-1, definition=SMOOTH STEP

0.0, 0.0, 0.1, 1.0, 1.0, 1.0

**

** MATERIALS

*Material, name=Material-1

*Density

1500.,

*Hyperelastic, mooney-rivlin

3.2e+06,800000., 0.

*Material, name=Material-2

*Density

2800.,

*Elastic

7e+10, 0.33

** INTERACTION PROPERTIES

*Surface Interaction, name=IntProp-1

** ----------------------------------------------------------------

** STEP: Step-1

*Step, name=Step-1

*Dynamic, Explicit

, 0.32

*Bulk Viscosity

0.06, 1.2

** BOUNDARY CONDITIONS

** Name: BC-1 Type: Displacement/Rotation

*Boundary

AC, 1, 3

Part1RP, 8, 8, 400000.00

** LOADS

** Name: Load-1 Type: Gravity

*Dload, amplitude=Amp-1

, GRAV, 9.8, 0., -1., 0.

** INTERACTIONS

** Interaction: Int-1

*Contact Pair, interaction=IntProp-1, mechanical constraint=KINEMATIC, cpset=Int-1

Part2outS, Part1outS

** OUTPUT REQUESTS

*Restart, write, number interval=1, time marks=NO

** FIELD OUTPUT: F-Output-1

*Output, field, variable=PRESELECT

** HISTORY OUTPUT: H-Output-1

*NODE OUTPUT, NSET=Part1RP

CVOL,PCAV

*Output, history, variable=PRESELECT

*End Step

** ----------------------------------------------------------------

** STEP: Step-2

*Step, name=Step-2

*Dynamic, Explicit

, 0.015

*Bulk Viscosity

0.06, 1.2

** BOUNDARY CONDITIONS

** Name: BC-1 Type: Displacement/Rotation

*Boundary, Op=New

AC, 1, 3

** OUTPUT REQUESTS

*Restart, write, number interval=1, time marks=NO

** FIELD OUTPUT: F-Output-1

*Output, field, variable=PRESELECT

** HISTORY OUTPUT: H-Output-1

*NODE OUTPUT, NSET=Part1RP

CVOL,PCAV

*Output, history, variable=PRESELECT

更多培训课程,学习资讯,课程优惠等学校信息,请进入 深圳福田区Solidworks产品设计培训深圳南山区Proe培训 网站详细了解,免费咨询电话:400-998-6158